Improper lockout top health and safety risk in Ontario pulp and paper industry

Improper or inadequate lockout of machines is a leading health and safety risk in sawmills. Failure to follow proper procedures often results in serious or fatal injuries.

What happened

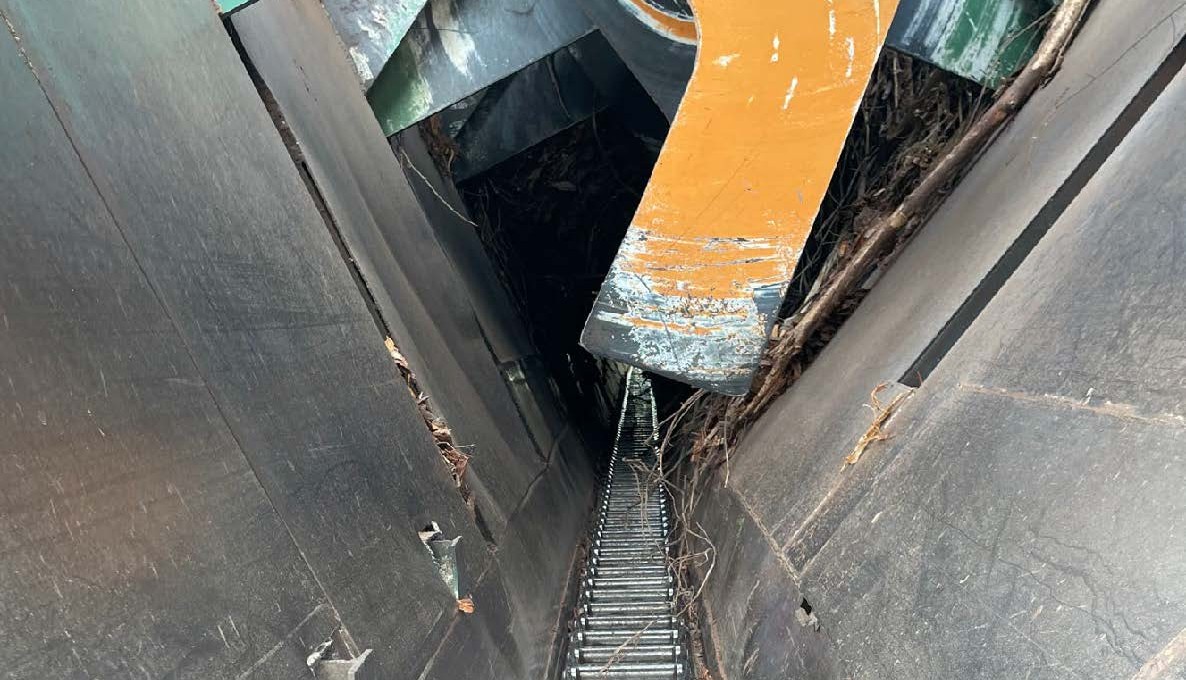

A millwright was fatally injured by a conveyor while working at a sawmill in Arkansas. After completing maintenance tasks in the log deck area, the worker began mechanically cleaning the log loader clean-up conveyor. During the task, the conveyor cycled. The equipment had not been locked out.

Why it happened

Lockout is a safety procedure used by industry to make sure dangerous machines are properly shut off and cannot be restarted during maintenance or repair. In this incident, the failure to lockout equipment properly was the main contributing factor.

According to Workplace Safety and Insurance Board data, injuries involving guarding and lockout rank among the top four causes of injuries in the pulp and paper industry. Research has shown the top 10 causes of inadequate or improper lockout of machines include:

- Lack of worker training and experience

- Incomplete or improper lockout; working on live or wrong equipment

- Lack of written procedures

- Outdated or inaccurate lockout sheets

- Inconsistent lockout or taking shortcuts

- Fatigue from shiftwork, long hours, or workload

- Stress, anxiety, or substance use

- Vulnerable workers such as young or inexperienced staff

- Poor safety culture or history of no lockout

- Interlock failures or improper sequencing

Prevention

Maintenance work must only be performed when the equipment is shut down and locked out. Workplaces should immediately focus on:

- Effective lockout training - Trainer competency, evaluation, site-specific and real-life scenario training, knowledge transfer

- Workplace health promotion - Address fatigue, mental health first aid, substance use

- Corporate lockout policy - Current and accurate procedures, enforcement, communication, annual review, roles and responsibilities, lockout methods (site-specific)

- Development of engineered solutions - Energy controls, artificial intelligence solutions

For more information on preventing injuries from hazardous equipment, contact your local health and safety specialist.

Related

Inadequate lockout top health and safety risk in Ontario corrugating sector | Workplace Safety North

Industry experts analyze causes of deficient lockout of machinery | Workplace Safety North

Top 10 health and safety risks in corrugating sector | Workplace Safety North

Lockout and Tagout Assessment Tool | Workplace Safety North

Workplace Health and Safety Snapshot for Ontario Sawmill Sector in 2024 | Workplace Safety North