Mining Hazard Alert

Mining Hazard Alert: Fall of ground near scissor lift in underground mine - Download and share

What happened?

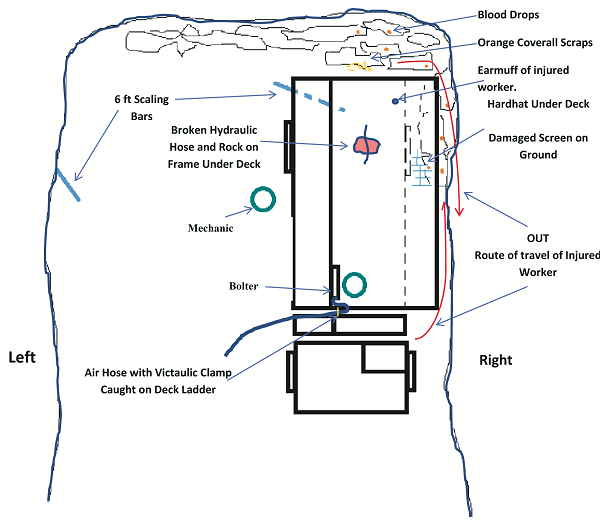

In a recent incident at an Ontario mine, a worker suffered serious head, chest and back injuries when ‘loose’ fell from the face of a heading.

Longer and stronger wall bolts had previously been installed in this heading due to talc conditions. The crew had finished supporting the back wall with screen and rebar, and were preparing to install support at the right wall, from the deck of a scissor lift. From there, they were going to install screen at the face.

During the process a hydraulic hose broke underneath the deck; a mechanic was then called in. The worker was helping the mechanic remove broken rocks on top of the rear axle under the deck.

The worker was behind the deck near the right side when loose rocks fell from the face, striking the worker and pushing him into the back of the deck. The injured worker crawled out along the right wall, and was transported to hospital.

Why did it happen?

Falls of ground and rockbursts have been responsible for numerous deaths and injuries in Ontario’s underground mines. Mining operations have long recognized these hazards and have developed comprehensive programs, procedures, and ground support standards to address them. Nonetheless, incidents still happen when working under unsupported ground, or because of failure to secure and make the workplace safe prior to working.

How could the incident have been prevented?

-

Never work or go under unsupported ground; caution must also be taken with an unsupported face or wall.

-

Always be on the lookout for changing ground conditions; check scale frequently.

-

If equipment breaks down before ground support has been installed or where other hazards exist, it should be moved to a safe location. Where the equipment cannot be readily moved, a non-routine hazardous task may have to be developed.

-

Always follow proper ground control communication procedures to report unusual ground conditions.